Black steel sheet thickness | Buy at a cheap price

You will select certain materials for your kitchenware or construction tasks

And for your objective, you wish to select a black steel sheet

You must take into account both the thickness and the weight while making your decision

Casting will result in the production of black sheet as the final product

It gets its name from the hue of its appearance, and the range of applications for it is incredibly broad thanks to the properties that it possesses

Although it is superior to other items in its category in a number of ways, it is not without flaws

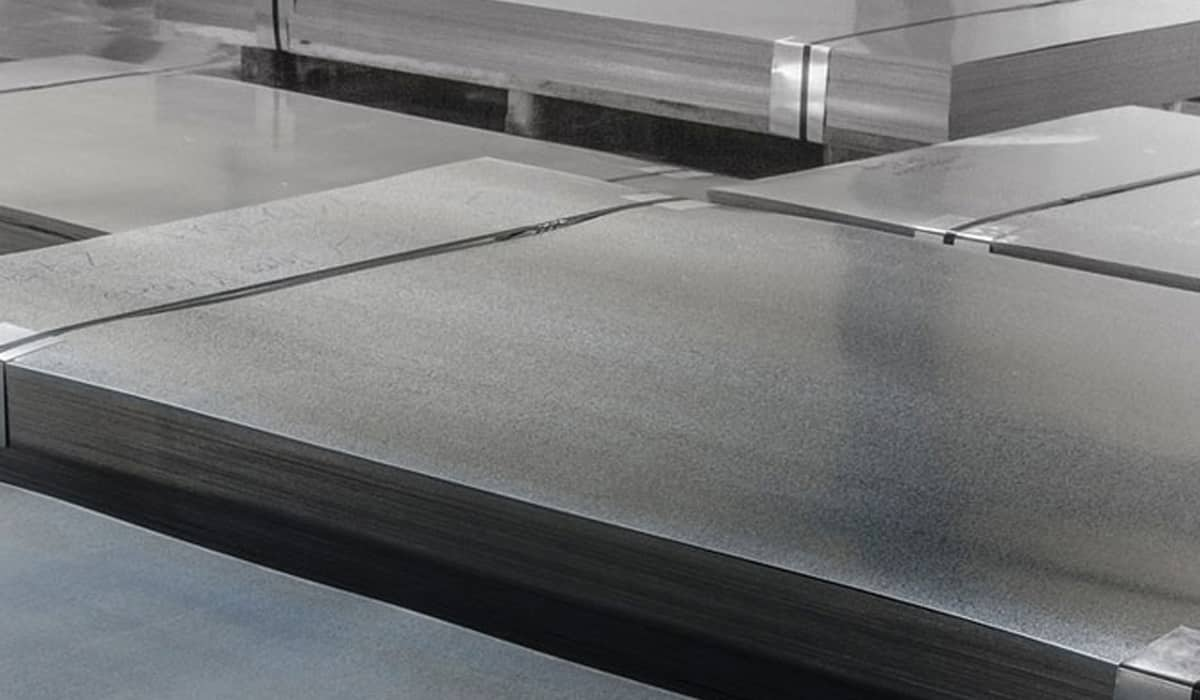

Black Sheet refers to what exactly

The word “black sheet” refers to the flat steels that are created as a result of the subsequent rolling of the goods that are created through the casting procedure

The manufacture of models made of mild steel involves the use of hot rolling

That is, the steel is initially heated to a point higher than the temperature at which it would crystallize

After that, rolling is done using rollers that are parallel to one another

At this time, one of the most essential advantages is the easier shape that the heated steel can take

Because of this benefit, products can be made to conform to the exact dimensions and thickness that are specified by the customer

Nevertheless, it is of the utmost significance that there are no delays at this stage of the creation of the black sheet

Because the sheet will begin to contract slightly as it begins to cool, and as a result, maintaining the desired form will be more challenging

As a result, there is a possibility that obtaining the ideal shape will not be achievable in the event of a delay

What are the characteristics of the Black Sheet?

An innovative manufacturing method is used to create mild steel

As a consequence of this, it possesses unique characteristics

The following is a list of the exceptional qualities that can be found in this one-of-a-kind product: It is appropriate for use in specialized manufacturing

It is possible to manufacture the desired dimensions because of the hot rolling process

It is generated as a result of the casting process

It has high strength

It is weldable

It is simple to weld and mold, which allows for a very broad range of applications for this material

The qualities of mild steel are typically those that are described here

High strength the product’s high strength and durability may vary depending on its thickness and shape

The thickness of mild steel can range anywhere from 1

5 to 20 millimeters, depending of the standard

As a result, there exist options that are very thin in addition to options that are very thick

black steel sheet weight

Using the steel weight calculator, you can determine the weight of various materials, including black sheet, depending on their dimensions and shapes

Black steel, sometimes known as black carbon steel, is a type of metal alloy that is made up primarily of iron and carbon, along with trace amounts of a number of other elements

Even though it may be melted and formed into virtually any shape we wish, pure iron is typically quite malleable

When added to pure iron, carbon has the ability to boost the strength of the metal, and the majority of forms of carbon steel contain between 1-2 percent carbon by weight

In most cases, black steel is produced during the manufacturing process of steel, which involves heating the iron to a high temperature in order to form a thin layer of oxidized iron

On the exterior of the steel, this layer of oxidized iron is produced

[Citation needed] Iron has a natural propensity to readily react with the oxygen that is present in the air

Iron oxide, also known as rust, is produced as a byproduct of this reaction

This rust growth might lead to the breakdown of some iron components and parts

For this reason, the surface of iron is frequently coated to prevent rust from forming on the surface

The fact that black steel has a naturally occurring anti-corrosion property as a result of the black iron oxide coating is a significant benefit of using black steel

The oxide layer has the potential to serve as a barrier, preventing oxygen from reaching the iron layer below it

Because a very thin oxide layer emerges when the iron is heated to a high temperature, it is not necessary to coat the iron

Pipes that transport gas or water in utilities typically are made of black steel

This is due to the fact that the manufacture of black steel is rather inexpensive, and the material can also be easily welded by employing conventional techniques that are fairly standard

This type of steel, which is resistant to rusting, is frequently used in the construction of long-distance plumbing networks

In addition, we are able to employ black steel in environments with ground conditions or climates that are susceptible to accelerating or modifying corrosion

Having said that, there are situations when we could require additional coatings or preventative strategies

Mild steel is a form of carbon steel that is extremely prevalent and contains a relatively low percentage of carbon by weight

This particular steel contains somewhere in the neighborhood of 0

2 percent carbon

Manganese, silicon, sulfur, and phosphorus are some of the other important elements that can be found in it

The manufacturing industry is the primary user of mild steel

On the other hand, we also make use of this material in the various pieces of equipment that we employ in our day-to-day lives

Mild steel is notable for not being brittle, which is a desirable quality in a metal

Additionally, it does not quickly submit to the process of tempering and possesses a great amount of strength

In addition to that, it has excellent electrical conducting properties

As a result, we are able to use it for welding

In addition, because it contains so little carbon, it can be formed easily into almost any shape

We can magnetize mild steel with relative ease because of the ferromagnetic qualities it possesses

In addition to that, the use of this material in structural applications is acceptable

However, in contrast to steel with a low carbon content, this material contains a higher concentration of carbon and is more prone to corrosion

black steel sheet thickness

The black steel sheet comes in thicknesses ranging from 0

5 mm to 6 mm

The metal plate is anything above that

Steel that has not been galvanized is known as black steel

The dark hue of the surface of the steel, which is caused by a coating of iron oxide, is where the name “black steel” originates from

This dark color gives the steel its name

This steel is essential for use in situations that do not require galvanized steel to be present

Steel is made by combining several different elements, the most important of which is carbon, with iron

This alloy can only include a maximum of 2 percent carbon based on its total weight

These alloys’ two most important features, high tensile strength and an affordable price, are both advantages

This is the most common type of material used in the building of many types of infrastructure

In addition to this, it is used in the production of various tools that are used in the construction industry

Black steel, commonly referred to as black carbon steel, is an alloy that consists primarily of iron and carbon, along with minute amounts of a number of other metals

Even though it is possible to melt and shape pure iron into any desired form, the material tends to be somewhat soft

The addition of carbon makes it possible to fortify iron in its purest form; the majority of variants of carbon steel have a carbon concentration of 1-2 percent

Black steel is often produced by oxidizing a thin coating of iron at a high temperature during the steel-making process

This can result in the production of black steel

On the surface of the steel, this layer of oxidized iron develops over time

In most cases, iron reacts speedily with the oxygen that is present in the air

The iron oxide that is formed through this process is more often known by the name rust

Due to the accumulation of rust, certain iron components could become defective

Coatings are routinely applied to the surface of iron in order to avoid the formation of rust on its surface

The inherent resistance to corrosion that black steel possesses as a result of its coating of black iron oxide is a considerable advantage

There is a possibility that the oxide layer acts as a barrier, stopping oxygen from penetrating to the iron layer below

Because of the high temperature, this very thin oxide layer forms on the iron, therefore it is not necessary to coat the iron

black steel sheet

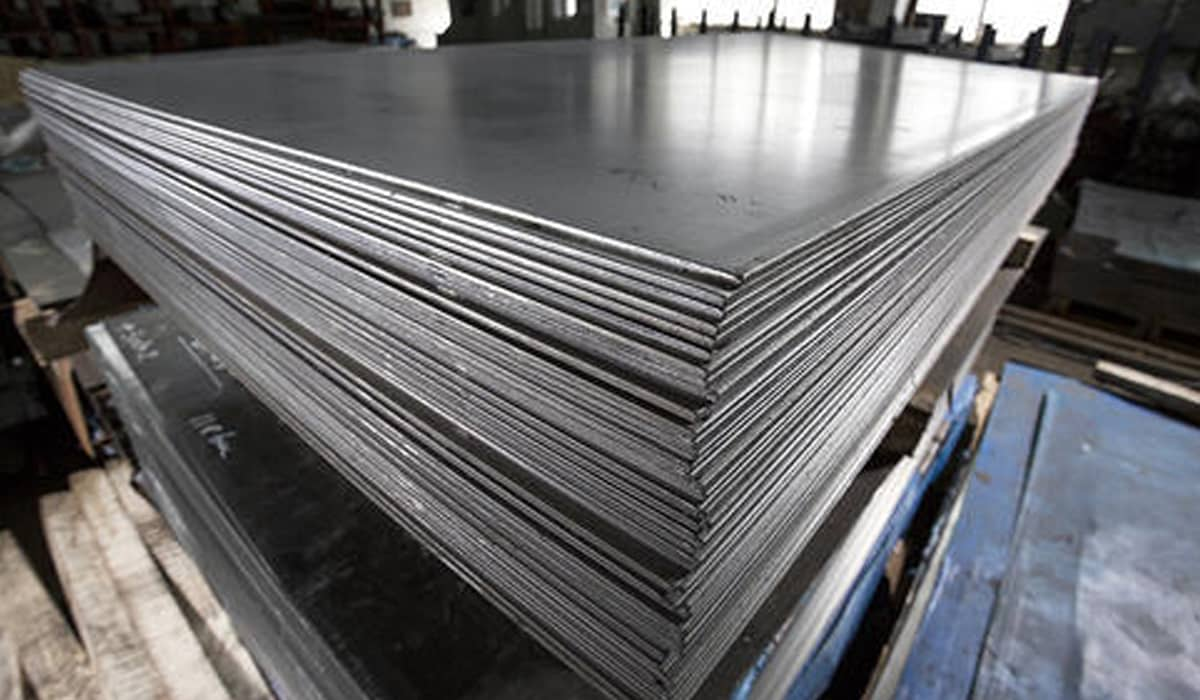

Sheet of mild steel Black Mild Steel comes in flat sheet form

By running the steel through rollers when it is above its recrystallization temperature to the correct physical dimensions, black steel entails the fabrication of sheet metal from billets

The term “steel sheet” refers to a piece of metal that started out as a flat sheet of steel and was eventually formed into a panel

A combination of iron and tin is used in the production of steel sheets, which can either be flat or coiled

Depending on the thickness of the steel, either basic tin snips or steel shears can be used to cut sheets of steel to the desired dimensions

They are shaped into a wide variety of components by employing a metal brake to undergo the bending process

The thickness of a steel sheet is typically referred to as the gauge

When the gauge value is increased, the material will be reduced in thickness, but when the gauge value is decreased, steel of a greater thickness and greater strength will be created

Steel sheets normally have a gauge that ranges from 8 to 30, despite the fact that certain commodities with a thinner or thicker gauge could be available for certain applications

Despite the fact that the thickness of these sheets can range quite a bit, they are typically referred to as “foil” or “leaf” due to the fact that they are so very thin

When a steel sheet has grown to be quite thick, it is often referred to as a “plate” instead of a sheet

In most cases, a plate cannot be bent using a metal brake, although a sheet can be bent with one

This is true despite the absence of any industry standards

The fabrication of a standard steel sheet involves the employment of a wide range of materials

Cold-rolled steel is by far the most common type of steel and also the most affordable

In spite of its widespread application, cold-rolled steel is susceptible to rust and corrosion over time when it is exposed to moisture or chemicals

This process can be accelerated by high temperatures

Throughout the manufacturing process, galvanized steel sheets have had zinc electroplated onto them to offer an additional layer of protection against corrosion

The most expensive steel sheets are produced of stainless steel, which is regular steel that has been alloyed with chromium to make it more resistant to corrosion and to give the steel a beautiful sheen

Iron and steel are the most common materials in the world

This is especially true in developing countries, where both of these goods are in high demand

As the economy grows, so does the need for a wide range of building materials

In this link, there is interaction between two people

When there is a large demand for basic resources like iron and steel in a country, this is a sign that the country is becoming more developed

Steel-based goods are used in many important industries, such as the automotive, building and construction, infrastructure, and electrical appliance parts industries, to name a few

We are in this business so that we can offer the best products to customers in every country in the world

Our products and services cover almost all of the different ways that goods can be put together and sent to your country

If you click on the link below, you can read more about the business and find out more about what’s going on: