We shall discuss what is marine-grade aluminum and used in boats.

Most metals on the market are not sold as items made of only one element. To obtain the properties of materials, metals are mixed with other elements to create an alloy, the characteristics of these alloys are called their grades.

Manufacturers choose grades based on the end use of the product. Many grades of aluminum are commercially available. Marine-grade aluminum is an alloy that can be exposed to sunlight and water due to its alloying elements.

Magnesium and silicon are the main additives that bring the alloy to marine grade. Some marine grades are more resistant to salt water, which puts more chemical stress on the metal. Marine-grade aluminum is used on boats, but can also be found on docks, railings, ladders, stairs, and other furniture or items commonly used on or near water.

Marine-grade aluminum can also be used in tanks or storage facilities: they are not intended for use in marine environments. While aluminum is commonly used in floating boats, it is rarely used in submarines. The compressive forces involved in diving wear down the aluminum, eventually leading to fatigue and cracking.

Additionally, continuous exposure to seawater in the absence of air can accelerate corrosion. What aluminum is used for boats? Choosing the right grade of aluminum means balancing cost, ease of manufacture, and alloy material properties.

Some alloys are easier to form or weld, which is an important manufacturing consideration in boat hull construction. Other alloys have very good corrosion resistance. Aluminum boats for the retail market, including products from major manufacturers Lund and Princecraft, are primarily made from 5052.

This wrought aluminum grade contains 2.2%-2.8% magnesium and 0.15%-0.35% chromium: these contribute to its corrosion resistance. Machining is only fair, however, so some boat parts may be made from other alloys. 6061 is an architectural silicon alloy with excellent corrosion resistance and is easier to machine, weld, and finish than 5052.

This aluminum is often used to increase strength or form parts that are not made with 5052. 6061 is more expensive, so only use it if the material and machining properties are worth the cost. 85% of aluminum is sold as wrought aluminum, but cast aluminum is sometimes used for special components that require a near-net shape outside of the mold.

The most common marine casting grade is A356, which is roughly equivalent to 6061. The silicon in 6061 helps the cast aluminum to register the details in the mold. Galvanic corrosion of aluminum Naval ships are often decorated with brass, bronze, or copper.

Stainless steel is also often used in marine environments due to its well-known corrosion resistance. These metals should be avoided in any connection to an aluminum boat. They can cause galvanic corrosion. Galvanic corrosion occurs when two metals that are far apart on the galvanic scale come into contact in an electrolyte bath.

The anode or active element gives ions to the inert metal or cathode and slowly erodes the anode. Aluminum metal is more reactive and releases many ions to any copper at a slower but still constant rate than stainless steel.

Aluminum is so reactive that it is sometimes used as a sacrificial anode. A piece of aluminum is attached to the steel hull of the boat or falls over the side of the net. Aluminum corrodes and helps protect steel. Galvanic corrosion is another reason why submarines are not made of aluminum.

Many of the components needed to run a submarine—such as nuclear reactors—must be made of other metals, which cause the aluminum hull to corrode more quickly on contact. Painting below the waterline (using epoxy paint) is one way to reduce the risk of galvanic corrosion, especially when moored near steel-hulled ships or underwater steel components.

Aluminum may not be the best for continuous immersion, but it is popular in boats, docks, pontoons, workplace furniture and ladders because it is light and strong. When the original aluminum is exposed to air and water (instead of being constantly submerged in water), the aluminum oxide that forms on the surface prevents further corrosion.

Grading: Common grades of 3000 series aluminum can oxidize rapidly in marine environments. If you are purchasing aluminum items for use in or around water, be sure to purchase items that are considered marine grade, either 5000 series aluminum or some manufacturer’s 6000 series.

With care and maintenance, these grades can increase the life of aluminum objects near water. Aluminum alloys are generally classified based on the main alloying elements added to the aluminum and the responsiveness of the alloy to heat and mechanical treatment.

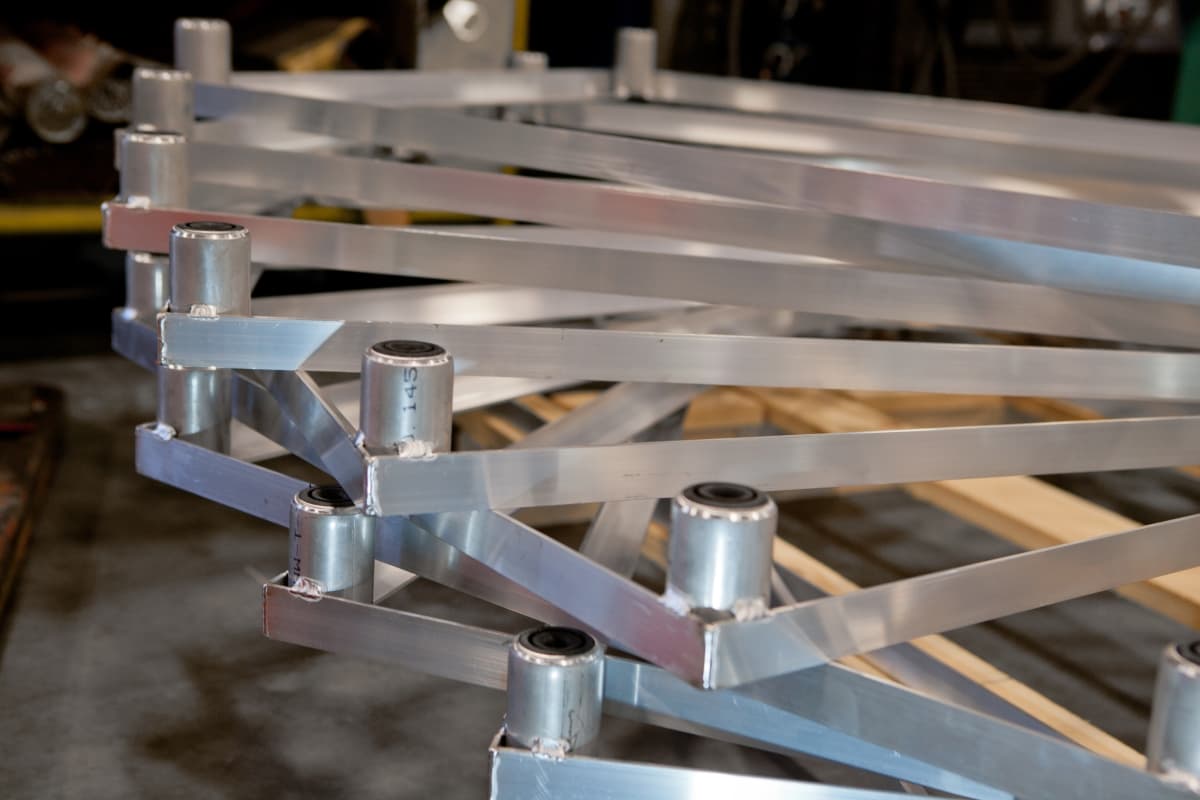

Marine-grade wrought aluminum alloys typically include aluminum-magnesium (Al-Mg) alloys and aluminum-magnesium-silicon (Al-Mg-Si) alloys. They are commonly used in structural shipbuilding, ship lifts, docks, and other marine structural applications.

Cast aluminum alloys are used in many marine applications because the casting process can produce relatively complex shapes including ship superstructures, structural components, interiors, and various supports. They are usually aluminum-silicon (Al-Si) alloys or Al-Mg alloys. Aluminum’s ease of use and compatibility makes it ideal for many industries.

For those in the marine industry, high-quality aluminum is an excellent material for lighter ships but offers significant advantages. It’s more reliable, cheaper, and more resistant to corrosion. Shipping wouldn’t be what it is today without marine-grade aluminum. We hope the above information will help you choose the best marine-grade aluminum for your next project.

We believe that with the right scores, you can create something beyond anything else! There are different types of aluminum suitable for use in aquatic environments. Marine-grade aluminum is typically in the 5000 to 6000 range.

If you plan to build a boat for yourself or work in the shipbuilding industry, you can choose from a variety of aluminum materials for your project. For our purposes, we will focus on the three most popular types of aluminum used in marine-related scenarios.

All information mentioned above providing to the buyers who want to know and buy metal steel products with professional and innovative thoughts, and passionate and enthusiastic attitudes.

Our vision is to be a standard for customized products and quality services so that we can build a good brand image for our company in the national and international markets with competitive prices and cheap shipping services. For more information kindly visit our site.

Your comment submitted.